UVLACK – Premium Industrial UV Coating Solutions

Introduction to UVLACK

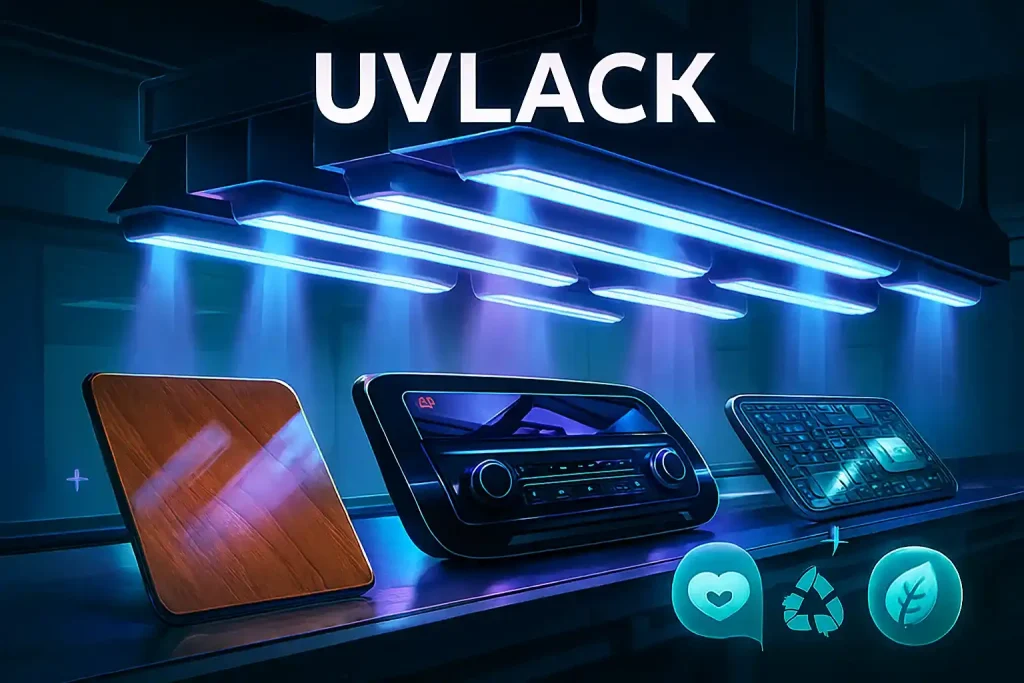

In today’s fast-paced industrial landscape, durability, efficiency, and sustainability are top priorities for manufacturers. Whether in furniture, automotive, packaging, electronics, or printing, businesses need coatings that not only protect surfaces but also enhance their visual appeal.

This is where UVLACK, a premium UV varnish coating solution, is redefining industry standards. Combining advanced polymer technology with rapid UV curing, UVLACK delivers a high-performance finish that is durable, eco-friendly, and cost-efficient.

Unlike traditional coatings that require long drying times or emit harmful chemicals, UVLACK offers instant curing under ultraviolet light and significantly lower VOC emissions. The result is a coating solution that increases productivity, reduces environmental impact, and provides unmatched surface protection.

This article explores UVLACK’s composition, features, applications, benefits, safety protocols, and industry case studies—showing why it has become the preferred choice for professionals seeking superior coating performance.

Composition and Features of UVLACK

At the heart of UVLACK’s success is its unique formulation, designed with advanced materials that provide both durability and versatility.

Key Components

- Acrylics & Urethanes: Deliver strength, adhesion, and flexibility.

- Oligomers & Photoinitiators: Ensure rapid curing when exposed to UV light.

- Additives: Enhance gloss retention, scratch resistance, and chemical durability.

Standout Features

- Instant UV Curing

When exposed to UV rays, UVLACK cures almost instantly, minimizing downtime in production. This allows manufacturers to meet high-volume demands without sacrificing quality. - Superior Adhesion

Bonds effectively to wood, metal, plastic, composites, and electronics, making it versatile across industries. - Gloss Retention & Aesthetic Appeal

Provides long-lasting shine, enhanced color vibrancy, and a polished finish that maintains its look over time. - Scratch & Chemical Resistance

Withstands harsh industrial environments, from daily wear to exposure to solvents and cleaning agents. - Eco-Friendly Performance

Low VOC emissions align with global environmental regulations, making it a responsible choice for modern industries.

By combining these properties, UVLACK delivers a premium industrial UV finish that meets the twin demands of aesthetics and performance.

How UVLACK Works

UVLACK relies on ultraviolet curing technology, which sets it apart from conventional varnishes.

The Curing Process

- Application – UVLACK is applied as a thin layer via spraying, brushing, or rolling.

- UV Exposure – Once exposed to UV light, photoinitiators in the varnish trigger a rapid polymerization reaction.

- Cross-Linking – Molecules bond tightly, creating a dense, protective layer.

- Instant Hardening – Within seconds, the coating solidifies into a durable finish.

Why It’s Superior

- Speed: Eliminates long drying times associated with solvent-based coatings.

- Efficiency: Reduces production bottlenecks, allowing faster turnaround.

- Durability: Creates a stronger, more resilient layer compared to traditional finishes.

The science behind UVLACK ensures maximum productivity and long-term surface protection with minimal environmental impact.

Applications of UVLACK

UVLACK’s versatility makes it a go-to solution across multiple industries.

1. Furniture Manufacturing

- Enhances wooden surfaces with high-gloss finishes.

- Protects against scratches, spills, and wear, ensuring long-lasting beauty.

2. Automotive Industry

- Applied on dashboards, trims, and interior panels.

- Provides UV resistance, preventing fading from sunlight.

- Maintains gloss even under constant use.

3. Electronics Manufacturing

- Coats circuit boards and components for moisture, dust, and chemical protection.

- Improves insulation and heat resistance.

4. Packaging Industry

- Used on luxury packaging and product labels.

- Adds a premium glossy finish while protecting against abrasion during transport.

5. Printing Industry

- Applied to brochures, business cards, and catalog covers.

- Enhances color vibrancy while protecting printed material from damage.

From functional protection to aesthetic appeal, UVLACK adapts seamlessly to different sectors, making it one of the most widely applicable UV coating solutions.

Benefits of UVLACK

The advantages of UVLACK extend far beyond surface-level beauty.

1. Unmatched Durability

Forms a robust barrier against scratches, abrasions, and harsh environmental conditions.

2. Rapid Curing

Instant UV curing reduces downtime and accelerates production efficiency.

3. Aesthetic Excellence

Maintains gloss, depth, and color vibrancy, giving products a premium, long-lasting appearance.

4. Eco-Friendly Solution

Low VOC emissions support sustainable manufacturing and compliance with environmental regulations.

5. Cost-Effectiveness

- Fewer reapplications required compared to traditional varnishes.

- Reduced labor and drying time lower overall costs.

6. Versatility

Adapts to wood, metal, plastics, composites, and electronics, allowing industries to streamline finishing processes with a single solution.

Together, these benefits position UVLACK as a market leader in industrial UV coatings.

How to Apply UVLACK

Proper application is key to achieving UVLACK’s optimal performance.

Step 1: Surface Preparation

- Ensure the surface is clean, dry, and grease-free.

- Use lint-free cloths and industrial cleaners for best results.

Step 2: Application

- Use a spray gun for even coverage or a brush for precision work.

- Mix UVLACK thoroughly according to manufacturer guidelines.

Step 3: Curing

- Expose coated surfaces to UV light immediately after application.

- The varnish cures within seconds, forming a dense, durable layer.

Step 4: Handling

- Allow sufficient curing time before final handling.

- Inspect for uniform gloss and adhesion.

This process ensures consistent quality, durability, and finish across all applications.

Safety and Handling of UVLACK

As with all industrial coatings, safety protocols are essential.

Key Safety Measures

- PPE: Always wear gloves, goggles, and masks to prevent skin or respiratory exposure.

- Ventilation: Apply UVLACK in a well-ventilated workspace.

- Storage: Keep containers sealed, away from sunlight and heat sources.

- Spill Management: Use absorbents and follow MSDS protocols for cleanup.

- Training: Ensure staff are trained in safe handling and emergency response.

By following these measures, manufacturers can use UVLACK safely while maintaining workplace health standards.

Comparison with Other Varnishes

How does UVLACK compare to other coating options?

| Feature | Traditional Solvent Varnish | Water-Based Varnish | UVLACK UV Coating |

|---|---|---|---|

| Drying Time | Hours to days | Moderate | Instant |

| VOC Emissions | High | Low | Very Low |

| Durability | Moderate | Lower than solvent | Superior scratch & chemical resistance |

| Gloss Retention | Limited | Moderate | High & long-lasting |

| Application | Multiple coats required | Multiple coats | Fewer coats, stronger adhesion |

| Cost Efficiency | High reapplication costs | Lower durability | Cost-effective long-term |

UVLACK combines the eco-friendliness of water-based options with the durability of solvent-based coatings, offering the best of both worlds.

Industry Feedback and Case Studies

Furniture Manufacturer

A leading furniture brand reported 30% faster production cycles after switching to UVLACK due to its rapid curing. Customer complaints about surface wear decreased significantly.

Automotive Body Shop

A car refinishing company found UVLACK’s resistance to scratches and UV fading superior to conventional coatings, improving customer satisfaction and reducing rework costs.

Electronics Manufacturer

By applying UVLACK to circuit boards, an electronics company improved moisture resistance and thermal stability, ensuring products lasted longer in demanding environments.

These real-world examples highlight UVLACK’s practical value across industries—not just in theory, but in measurable results.

Conclusion

UVLACK is more than just a coating—it’s a solution.

With its advanced formulation, instant curing, superior durability, and eco-friendly profile, UVLACK has set a new standard for industrial UV coatings. From furniture to automotive, electronics to packaging, it offers manufacturers a reliable way to enhance both performance and aesthetics.

By choosing UVLACK, businesses are investing in:

- Efficiency – faster curing, reduced downtime.

- Durability – stronger protection against scratches and chemicals.

- Sustainability – lower VOC emissions and eco-friendly production.

- Cost Savings – fewer reapplications and longer product lifespan.

As industries continue to demand solutions that balance performance, beauty, and sustainability, UVLACK stands out as a premium choice for the future of coatings.

✨ If you’re looking to elevate your products with a finish that lasts and impresses, UVLACK is the smart investment.